| Item | Unit | Specification | Remark | |

|---|---|---|---|---|

| Engine (Cummins) | Model | - | QSB6.7-C260 | Produced by Cummins |

| Rated Power | kW | 194 | ||

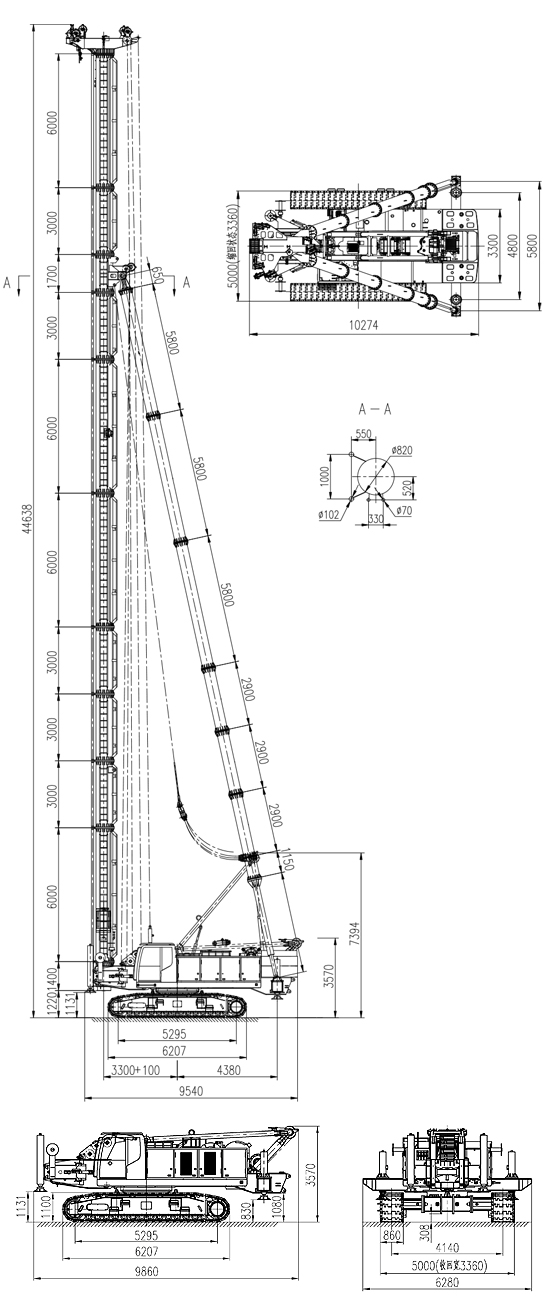

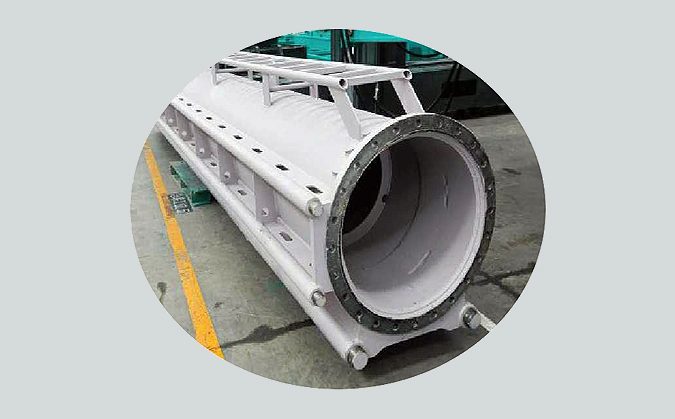

| Piling Frame Vertical Mast |

Length | m | 21, 24, 27, 30, 33, 36, (39), (42) | |

| Diameter | mm | Ø820 | ||

| Main Guide | mm | Ø102X1000 | ||

| Auxiliary Guide | mm | Ø70X330 | ||

| Maximum Allowable Pulling Force | kN(t) | 666(68) | ||

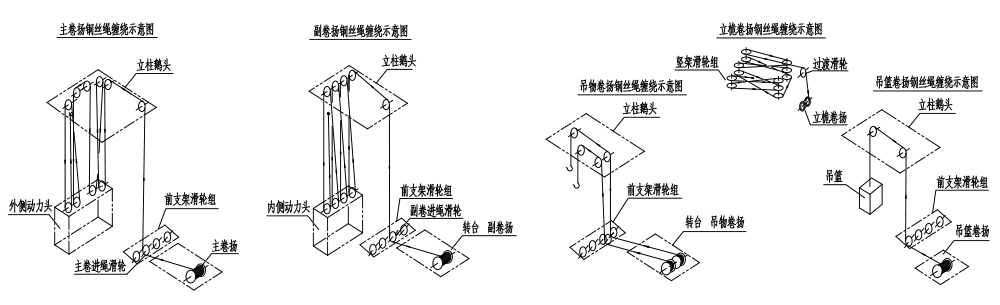

| Outer Hoist | Single Line Speed | m/min | 96/48 | Includes fine speed & floating drilling functions |

| Single Rope Tension | kN | 98 | ||

| Wire Rope Diameter | mm | 20 | ||

| Rope Capacity | m | 550 | ||

| Inner Hoist | Single Line Speed | m/min | 96/48 | Includes fine speed & floating drilling functions |

| Single Rope Tension | kN | 98 | ||

| Wire Rope Diameter | mm | 20 | ||

| Rope Capacity | m | 450 | ||

| Lifting Hoist 1/2 | Single Line Speed | m/min | 43 | Includes fine speed & floating drilling functions |

| Single Rope Tension | kN | 98 | ||

| Wire Rope Diameter | mm | 20 | ||

| Rope Capacity | m | 130 | ||

| Mast Installation Hoist |

Single Line Speed | m/min | 47 | |

| Single Rope Tension | kN | 98 | ||

| Wire Rope Diameter | mm | 22/44 | ||

| Rope Capacity | m | 226 | ||

| Basket Hoist | Wire Rope Diameter | mm | 14 | |

| Rope Capacity | m | 110 | ||

| Main Body | Crawler Extended | mm | 5000 | |

| Crawler Retracted | mm | 3360 | ||

| Crawler Width | mm | 860 | ||

| Crawler Length | mm | 6207 | ||

| Distance Between Tumblers | mm | 5295 | ||

| Travel Speed | km/h | 0.6~1.1 | ||

| Rotation Speed | r/min | 0.5~1 | Rotation Angle 360° | |

| Gradeability | ° | 21.8 (40%) | Main body only | |

| Overall Dimensions (LxWxH) |

Working State | m | 10.5x6.3x38.7 | |

| Transport State | m | 10.7x3.6x3.57 | ||

| Weight | t | 19 | ||

| Maximum Permissible Traveling Weight |

t | 160 | When equipped with working attachments, please refer to the user manual for details |

|

| Ground Contact Area | m2 | 9.107 | ||

| Ground Pressure | MPa | 0.172 | ||

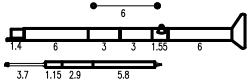

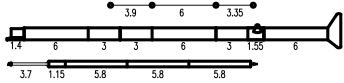

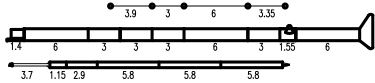

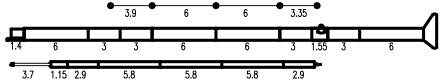

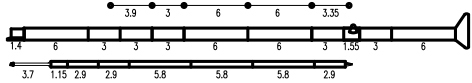

| 21M |  |

|---|---|

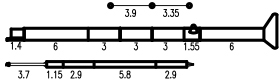

| 24M |  |

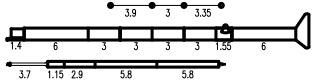

| 27M |  |

| 30M |  |

| 33M |  |

| 36M |  |

| 39M |  |

| 42M |  |

| Leader | Working Equipment | Hammer | Generator Weight (t) | Safety Angle (without pile) |

Total Weight (without pile) (t) | Average Ground Pressure (without pile) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Length (m) | Upper Auger | Lower Auger | Screw | Casing | Model | Weight (t) | Cap Weight (t) | Auxiliary Leader Weight (t) | ||||||||||

| Model | Weight (t) | Model | Weight (t) | Length (m) | Weight (t) | Length (m) | Weight (t) | Front/Back | Left/Right | MPa | Kg/cm2 | |||||||

| 40 | JUA-150P | 7.3 | JLA-150P | 8.5 | 36 | 7.2 | 33 | 4.554 | JC70 | 7.2 | 0.2 | 1.1 | 5.594 | 8.8 | 10.9 | 152.933 | 171 | 1.74 |

| 37 | JUA-150P | 7.3 | JLA-150P | 8.5 | 33 | 6.6 | 30 | 4.140 | JC70 | 7.2 | 0.2 | 1.1 | 5.594 | 9.7 | 11.6 | 150.743 | 169 | 1.72 |

| 34 | JUA-150P | 7.3 | JLA-150P | 8.5 | 30 | 6.0 | 27 | 3.726 | JC70 | 7.2 | 0.2 | 1.1 | 5.594 | 10.9 | 12.7 | 148.168 | 166 | 1.69 |

| 31 | JUA-150P | 7.3 | JLA-150P | 8.5 | 27 | 5.4 | 24 | 3.312 | JC70 | 7.2 | 0.2 | 1.1 | 5.594 | 12.2 | 13.8 | 145.838 | 163 | 1.66 |

| 28 | JUA-150P | 7.3 | JLA-150P | 8.5 | 24 | 4.8 | 21 | 2.898 | JC70 | 7.2 | 0.2 | 1.1 | 5.594 | 13.7 | 15.2 | 143.458 | 160 | 1.64 |

| 25 | JUA-150P | 7.3 | JLA-150P | 8.5 | 21 | 4.2 | 18 | 2.484 | JC70 | 7.2 | 0.2 | 1.1 | 5.594 | 15.6 | 16.7 | 140.933 | 158 | 1.61 |

| 22 | JUA-150P | 7.3 | JLA-150P | 8.5 | 18 | 3.6 | 15 | 2.070 | JC70 | 7.2 | 0.2 | 1.1 | 5.594 | 17.7 | 18.5 | 138.553 | 155 | 1.58 |

| Category | Details |

|---|---|

| Stability | Ensures outstanding stability and has obtained proprietary intellectual property certifications |

| Structural Design | The π-shaped cross beam intersecting the central chassis shaft supports both sides, maintaining stable connections even when the crawlers are fully extended |

| Transport Convenience | Transport possible without separating the crawlers, enabling wider crawler extension within the same transport width |

| Technical Advantage | Achieves industry-leading performance in terms of structural specifications, stability, and maximum vertical mast height |

| Patent Certification | Granted invention patents in China, Japan, and Korea |

| Category | Service Details |

|---|---|

| Pre-Sales Service |

- Customer consultation and technical proposals - Support for selecting equipment suitable for ground conditions - Custom design and manufacturing - Provision of technical training |

| During-Sales Service | - Faithful execution of contracts and commitments |

| After-Sales Service |

- Equipment installation and commissioning, on-site operator training - Prompt resolution of field issues - Timely supply of spare parts - Regular maintenance service - Scheduled customer visits and feedback collection |

Tel: +82-31-280-2890 / +82-31-280-2891 Fax: +82-31-280-2892 Person in charge of personal information: Yang Ji-Ahn

Note) Leader Assembly

- Based on the length at the top of the holder, the sequence of assembly can be adjusted according to site conditions and does not affect safety.